Simplify3D

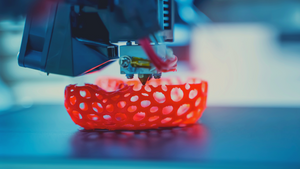

Reduce Prototyping Costs with 3D Printing and 3D CAD!

Folks often approach our team at 3DChimera with only an idea or a drawing of the product they want made. So how can 3D Printing, 3D CAD and 3DChimera reduce prototyping costs for them?

Read more

Advanced Manufacturing Olympics 2020 - TDP Challenge

The goal of this challenge is for participants to accurately recreate a 3D printed part from an existing Technical Data Package using innovative techniques...

Read more

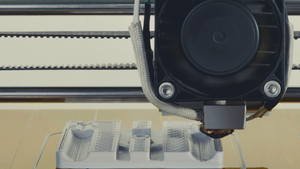

When to save a Factory File vs. GCode in Simplify3D

In this video we outline the differences between a Factory File and GCode from Simplify3D 3D printing slicer software.

Read more

Aug 24, 2018

Optimize for STRENGTH with Simplify3D & innovatiQ 3D Printers

There are many characteristics to consider when optimizing for strength. Obviously, this is highly dependent upon the material properties of your filament. It is also highly dependent on...

Read more

Aug 22, 2018

Optimize for SPEED with Simplify3D & innovatiQ 3D Printers

To optimize for Speed on an innovatiQ printer, you need to consider the layer size (similar to optimizing for surface finish...only opposite). In this case...

Read more

Aug 20, 2018

Optimize for SURFACE FINISH with Simplify3D & innovatiQ 3D Printers

We can optimize surface finish on any German RepRap 3D Printer with Simplify3D (our slicer software). Surface finish is a function of layer size and nozzle size. The small both are....

Read more