GRR

When to save a Factory File vs. GCode in Simplify3D

In this video we outline the differences between a Factory File and GCode from Simplify3D 3D printing slicer software.

Read more

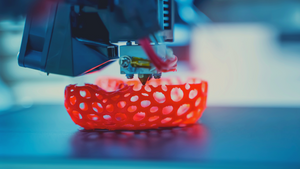

FFF: Nozzle Sizes Demystified

Nozzles can be a confusing topic in 3D printing, mainly because it feels intuitive that a smaller nozzle sizes would provide for a better finish. This is simply not true. When thinking about nozzle size there are really 2 things to consider...

Read more

Aug 22, 2018

Optimize for SPEED with Simplify3D & innovatiQ 3D Printers

To optimize for Speed on an innovatiQ printer, you need to consider the layer size (similar to optimizing for surface finish...only opposite). In this case...

Read more

Aug 20, 2018

Optimize for SURFACE FINISH with Simplify3D & innovatiQ 3D Printers

We can optimize surface finish on any German RepRap 3D Printer with Simplify3D (our slicer software). Surface finish is a function of layer size and nozzle size. The small both are....

Read more

Industrial vs. Consumer 3D Printers

Sure, "Industrial Quality" sounds like something you want...but what does it mean? If you have spoken with us about 3D printing, you most certainly have heard us mention "Industrial Quality"...

Read more