Sintratec Kit

Reduce Prototyping Costs with 3D Printing and 3D CAD!

Folks often approach our team at 3DChimera with only an idea or a drawing of the product they want made. So how can 3D Printing, 3D CAD and 3DChimera reduce prototyping costs for them?

Read more

Jan 27, 2022

How You Can Take Control of Your Supply Chain with Additive Manufacturing

It seems that every year is now the year of "Supply Chain Problems". From back-to-back international holiday schedules...

Read more

How Strong Are SLS Printed Parts?

A question we often get asked is “How strong are SLS printed parts?”. One option is to have your Sintratec Kit prints parts out of a nylon (PA12) powder, which is fused together by a laser. This method raises questions of strength...

Read more

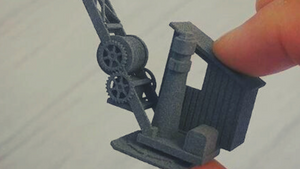

How Much Can You Fit In Your Sintratec Kit?

The Sintratec Kit is a compact but mighty desktop SLS printer that can be packed full of parts for printing. Since each layer takes about the same time, whether it's 1 part or 64 parts, it is more effective...

Read more

Oct 23, 2019

Thinking Outside the Box

Many people look at the Sintratec Kit and believe the build volume is too small for their application. It’s true that the recommended 90 x 90 x 110 mm build volume would be too small to print many kinds of tall parts. However, there are still ways to print large parts...

Read more

Sintratec Kit Quality - Proof is in the Prints

Given the low price point of the Sintratec Kit, we often get customers who wonder if the Sintratec Kit is really able to deliver quality results. Can the Sintratec Kit simultaneously be...

Read more

Aug 24, 2018

You like HP MJF parts? Then you will LOVE Sintratec SLS parts!

If you have been watching the 3D printing industry at all over the last year, you could not miss the appearance of HP in the 3D printing market. Frankly, the quality and surface finish on these parts is...

Read more

Aug 20, 2018

Desktop SLS for FabLabs, Makerspaces & Innovation Studios

SLS (Selective Laser Sintering) 3D Printers have been available for years, but typically command huge price tags in the $100k-250k range. With that introduction of Desktop SLS 3D printing...

Read more

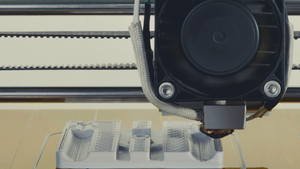

Desktop SLS - Can a kit really deliver?

The Sintratec Kit is designed by professionals, for professional use and delivers all of the power of SLS 3D printing in a small form factor (about the size of a microwave).

Read more