Jul 03, 2022

Reduce Prototyping Costs with 3D Printing and 3D CAD!

Folks often approach our team at 3DChimera with only an idea or a drawing of the product they want made. That drawing may be on the back of a napkin or a CAD rendering. The next step in the design process is to see the idea in real life: to hold something physical in their hands. This is the prototype stage. It’s a word we’re all familiar with, but let’s give Merriam and Webster a moment to define the term for us:

Prototype:

- An original model on which something is patterned

- An individual that exhibits the essential features of a later type

- A standard or typical example

- A first full-scale and usually functional form of a new type or design of a construction (such as an airplane)

Ok – so that runs a pretty big gamut from “essential features” to “usually functional form”. Can we also take a moment to note that Merriam-Webster decided that airplane is the appropriate example in definition #4?! Like, couldn’t they have chosen a smaller prototype – was cruise ship taken?

So how can 3D Printing, 3D CAD and 3DChimera reduce prototyping costs for our afore-mentioned folks? First, let’s look at the 3D CAD.

Prototyping with 3D CAD

Ideally, the concept would be rendered in a 3D CAD software by the time 3DChimera is approached for support, but we often don’t live in an ideal world. It takes skill, experience, and a deep understanding of all the print parameters to go from a sketch on paper to translating it to a 3D model, especially one that is designed for advanced manufacturing (DfAM)

The DfAM process will take into account:

- The specific 3D printer

- The type of material to be used (based on desired properties)

- The time to print

- Interior geometry (sparse infill vs. solid)

- Post-processing needs

You could satisfy definitions #1-3 for “Prototype” with just a CAD model. You could also create a suite of models that answer a variety of possible questions or outcomes you have, like what if the piece is hollow or how much pressure can it withstand before failing?

But it’s far more fun to hold the idea in your hand, instead of rotating a model on a screen, right?!

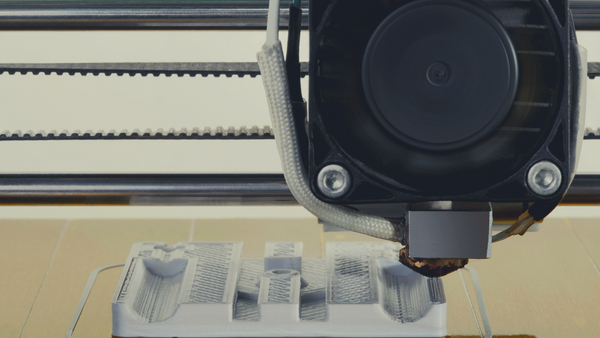

Prototyping with 3D Printing

The model is complete, it’s been designed for advanced manufacturing, and you are positive that after the first 3D print you’ll have a perfect specimen (definition #4). Dreams can come true, right?

How do we make sure that you get to an ideal prototype faster and with less cost? A lot of the work goes into the front-end of designing the piece using the DfAM process and working with a skilled technician. Following that, you can shorten the cycle and reduce the number of prints necessary to produce the required prototype by working with experts in 3D printing.

There are a couple interesting ways to navigate the essential iterations:

- You can print multiple versions of the model at the same time (using the earlier idea to create a suite of models)

- You could print “rough drafts” sooner to evaluate issues, errors, and positive outcomes to refine the CAD file

- Work with a 3D printing team that can print multiple materials on multiple printers to evaluate the strengths and weakness inherent in each set-up.

We hear from customers that so much of the joy in product development comes from the design and prototype stages of their journey. It’s where the magic happens. Once your design is locked in, the prototype makes it to definition #4, where it then goes to manufacturing.

Let’s discuss why it’s nearly impossible to jump from 3D CAD models to manufacturing, overlooking the whole 3D printing process.

- Traditionally, the first step in conventional manufacturing has been to cast tools, dies, or molds for the injection molding process. Getting started with injection molding can easily run tens of thousands of dollars, and if you don’t have your physical prototype yet, any mistake will be costly.

- If you are working with flexible parts, 3D printing in a flexible material (like TPE) is literally the only way to create the physical prototype before going to molding. There is no solution for this in conventional manufacturing.

3DChimera has been helping inventors, entrepreneurs, startups and Fortune 500 companies through this design cycle for nearly a decade. Learn more about our product development services.

“Alex and his team at 3DChimera are very professional, knowledgeable of existing and emerging technologies, and flexible to meet your Product development needs. They partnered with our team on several initiatives and was our go to team in support of our fast-paced timelines. I encourage you to engage with them on a program soon!”

- Michael, Designer @ Fortune 100 Company

“They’ve helped me design and print over 10 unique pieces for my business. Every time it’s been great.”

- Christian, Founder & CEO, Miami-based startup

The 3DChimera team has identified and tested the best tools to help you take control of your supply chain. Depending on what you need, we have a solution!

3D CAD for Prototyping:

| Ansys SpaceClaim |

| Simplify3D |

| SOLIDWORKS |

3D Printers for Prototyping:

| German RepRap x400 | FFF 3D Printer |

| MakerBot METHOD X Carbon Fiber Edition | FFF 3D Printer |

| MakerBot METHOD | FFF 3D Printer |

| Sintratec Kit | SLS 3D Printer |

Read More On Prototyping

Here are a couple stories we’ve shared before about the success in transitioning to an advanced manufacturing prototyping process:

- 4 Reasons to Prototype with 3D printers

- A webinar on prototypes to production

- TDP prototype challenge from the US Air Force

- 3 Ways to Grow with Additive Manufacturing; a webinar

- Product development in a remote work environment; a COVID-19 review

- Tips & Tricks: Design for Additive Manufacturing

There are opportunities to create rapid and lasting change in your organization by embracing advanced manufacturing in the prototyping process. If you have ideas, but aren't sure if the specs will work, the team at 3DChimera will help validate your concept against best practices in advanced manufacturing.