3D CAD

Dec 17, 2025

How to Manage Files on the 3DEXPERIENCE Platform (Setup, Saving, and Sharing)

The 3DEXPERIENCE Platform introduces a different way to manage SOLIDWORKS files, and many teams struggle with setup, navigation, and sharing early on. This guide explains how to use the 3DEXPERIENCE Platform for file management, including Collaborative Spaces, Bookmarks, saving files from SOLIDWORKS, and sharing designs for review.

Read more

The Playbook for Modern Manufacturing: Agility, Control, and Additive

Manufacturing isn't what it used to be. The old playbook doesn't cut it anymore. In this article, I share the three things we see separating the teams that are thriving from the ones that are stuck: agility, control, and additive. Plus, real examples of how companies are using these tools to solve real problems and stay ahead.

Read more

SOLIDWORKS Training Made Easy: What’s Available and How to Use It

We’ve been helping small and medium-sized teams get up and running with SOLIDWORKS for years. One of the biggest struggles we see is when a company buys a license, installs the software, and then gets stuck. MySolidWorks is one of the easiest ways to stay unstuck.

Read more

How to Change Your SOLIDWORKS Desktop Serial Number (Standalone)

Changing your SOLIDWORKS Desktop serial number for a standalone installation is quick and hassle-free. This guide walks you through deactivating your current license, updating the serial number via the installation manager, and reactivating the software—all without reinstalling SOLIDWORKS Desktop. Follow these steps to keep your software running smoothly!

Read more

Minimum and Recommended PC Requirements for SOLIDWORKS CAD Software

When investing in CAD software like SOLIDWORKS, ensuring that your PC setup meets the necessary specifications to handle its powerful features efficiently is essential.

Read more

Predictions for 2023: Advanced Manufacturing Poised for Explosive Growth

As we enter 2023, all the supply chain & logistics challenges that began with the start of the pandemic continue to plague just about ...

Read more

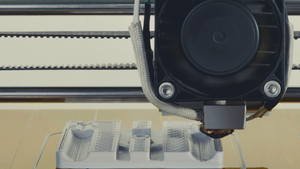

Reduce Prototyping Costs with 3D Printing and 3D CAD!

Folks often approach our team at 3DChimera with only an idea or a drawing of the product they want made. So how can 3D Printing, 3D CAD and 3DChimera reduce prototyping costs for them?

Read more

Streamlining your Inventory to Save Money

Discover how advanced manufacturing can revolutionize inventory management for industrial enterprises. Learn how 3DChimera can assist with CAD, 3D printing, and post-processing, enabling you to become your own supplier and optimize production processes.

Read more

Can The Tooling Process Be A Hidden Money Saver In Your Business?

Any change in tooling has a direct impact on the production line’s quantity, quality, and pricing, further impacting a business’ bottom line.

Read more

How Do You 3D Print A Tortoise Shell?

Using our team's deep expertise in 3D scanning, materials, and 3D printing, we were able to come up with a lifelong solution for our new friend, George.

Read more