Jan 24, 2022

Tips & Tricks: Design for Additive Manufacturing

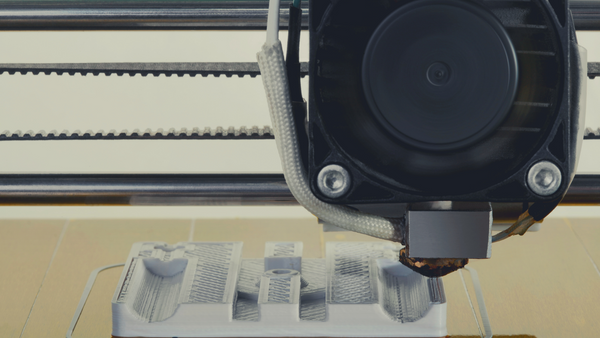

Sharing tips and tricks for designing parts that take advantage of the SLS 3D printing process!

Our team will share tips and tricks for designing parts that take advantage of the SLS (Selective Laser Sintering) 3D printing process. You will leave this session with practical DfAM (Design for Additive Manufacturing) knowledge that you can immediately put to use for prototypes and short run production with this promising additive manufacturing process.

- Appropriate tolerances / fits for SLS 3D printed parts

- Effect of part orientation on SLS 3D printed parts

- Optimal geometry considerations for SLS 3D printed parts

DfAM with 3DChimera

DfAM enables manufacturers and small businesses alike to cost-effectively produce parts in ways traditional manufacturing methods cannot. Understand the best practices in design for this medium can decrease warehousing and manufacturing costs, shorten lead times, reduce risk, and stay agile by 3D printing spare parts.

With the help of an expert like 3DChimera, we can quickly work with your team to run an Additive Assessment to identify if your part or process is ready for 3D printing. Contact us today to get started.