Aug 20, 2018

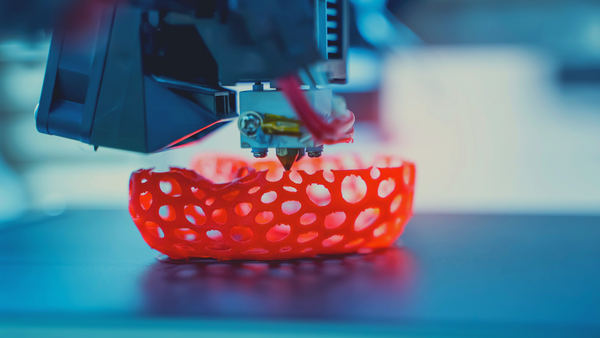

Optimize for SURFACE FINISH with Simplify3D & innovatiQ 3D Printers

We can optimize surface finish on any innovatiQ (formerly German RepRap) 3D Printer with Simplify3D (our slicer software). Surface finish is a function of layer size and nozzle size. The smaller both are, the better it looks. The tradeoff is print time, the smaller the layer and nozzle size are, the longer it takes to print. The relationship is linear.

For example, a part that takes 2 hours to print with a 0.4mm nozzle with 0.2mm layers, will take 4hrs with the same nozzle and 0.1mm layers.

It follows like this chart:

innovatiQ (formerly German RepRap) 3D printers are capable of a 0.02mm layer thickness (very fine finish), but it usually does not make sense to print like that. Most of the time we print at 0.2 or even 0.3mm layers to save on print time with a high quality surface finish. By comparison, Stratasys usually prints at 0.254mm layers (0.01in).

So, the innovatiQ standard size is usually better than Stratasys out of the box....but it is capable of MUCH more, which Stratasys cannot do. Further, innovatiQ 3D printers have the ability to print with multiple layer thickness in the same part to optimize for both print quality and print time. Another area where you have no control with a Stratasys printer.