Aug 21, 2018

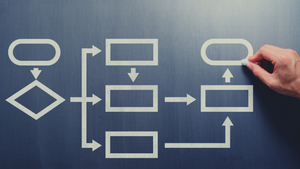

3D Scan to CAD - Workflow Explained

Many of our customers who purchase 3D Scanners are interested in generating STEP data to import into their CAD system of choice (Solidworks, Creo, ProE, Inventor, etc).

Often, these customers are surprised to learn that CAD formats (STEP, IGES, etc) are a standard output format for 3D scanners. In fact, most 3D scanners generate data in a STL format, which is mesh based data. If you have ever tried to import an STL in your CAD system, you will understand why this is a problem...

Without getting too far in the weeds, your CAD data can easily be converted INTO an STL file (after all this is the standard format for 3D printing). BUT, you cannot easily generate a CAD file FROM an STL file. A good analogy to consider is a Word Doc vs. a PDF...both are useful, but not necessarily backwards compatible.

Ok, so what can we do?

Fortunately, there a number of software solutions out there to help with this process, which is often referred to as Reverse Engineering. Our two favorite software solutions are Geomagic (available stand alone or as a Solidworks plugin) and SpaceClaim. Both of these tools will give you the ability to extract curves, planes, cylinders, etc. from your 3D scan data. In the case of Geomagic, there is even an "autosurface" tool which is quite good for quickly generating editable data for Solidworks.

If adding a new software tool to the mix feels too complex or out of budget at the moment, 3DChimera has a service to help you out - STL 2 STEP