Sep 12, 2023

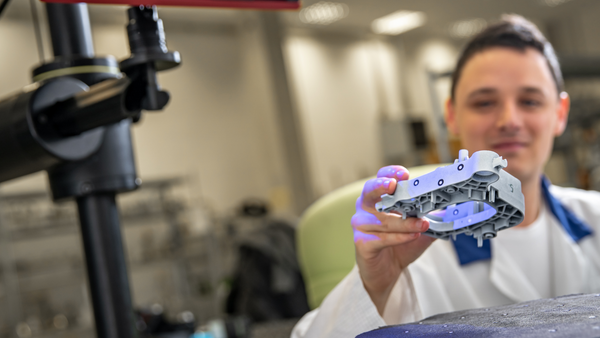

Why 3D Scan? Here's 12 real-world examples for engineers!

3D Scan for Reference Data

-

When you require precise 3D data for the mating surfaces of a technological accessory intended for a leading competitor's product.

- For cases where you aim to model an object after an unrelated product in the real world, perhaps inspired by the shape of a cookie jar for an upscaled pet product in your lineup.

3D Scan for Reverse Engineering

- Initiating a digital CAD database for any product where the CAD data is either non-existent or lost.

- Scanning a competitor's product to initiate a CAD database for a complex feature with intricate organic surfaces that prove challenging to measure by hand.

3D Scan for Inspection

-

Ensuring that newly manufactured parts align precisely with your CAD database for a first-article inspection, particularly critical when building a new part.

- Swiftly scanning a batch of parts from each production line to verify compliance with your Acceptable Quality Level (AQL).

3D Scan for Archival

- Digitally copying a valuable part from a borrowed object for future reference, ensuring accessibility for months to come.

- Safeguarding the data of old inventory without an original CAD database, by performing a scan to archive it indefinitely.

- Digitizing custom fixtures/tooling fabricated on the manufacturing line, enabling redesigns for enhanced efficiency across the entire production process.

- Creating digital models of critical hand-built tooling/fixtures to serve as backups, mitigating the risk of production halts due to damage.

- Investigating quality issues by studying pre- or post-production scanned objects, crucial in identifying areas for design improvements.

- Monitoring the wear and tear of production tooling over time by scanning parts directly off the production line.

Should any of these scenarios resonate with challenges your team has faced in the past, we're here to discuss how 3D scanning can make a tangible difference in your operations.

Do any of these scenarios raise a flag for an issue your team has experienced in the past?