From Problem to Production:

Keep operations moving, no matter the challenge.

From concept to delivery, we provide a seamless end-to-end experience.

The Problem We Solve

Designing and printing a functional part sounds easy—until it's not.

We do the hard work up front—so you don't have to.

Most additive projects fail because of unpredictable variables: the wrong material, bad geometry, poor tuning. That's where we come in.

Printer. Materials. Results. Dialed in.

We do the design, testing, and tuning—so what you receive isn’t just equipment, it’s a working solution.

Your parts, on demand—like a vending machine.

Pre-loaded with the files, materials, and settings you need—just press start and get reliable, ready-to-use parts.

CALL US TO GET STARTEDTurnkey Solution

A Fully-Validated 3D Printing System—Delivered Ready to Run

We take your part or idea and turn it into a production-ready 3D printing system—fully validated and ready to run. Whether starting from a physical object or a CAD file, we digitize, optimize, and lock in every detail for repeatable success.

✅ 3D Scanning (as needed)

✅ Design for Additive Manufacturing (DfAM)

✅ Material & Technology Selection

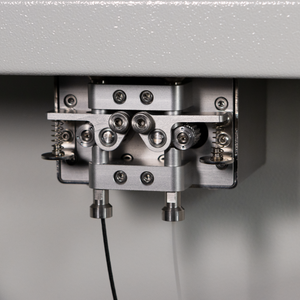

✅ Print Parameter Tuning (200+ variables optimized for performance)

✅ Functional Prototypes Delivered & Approved

✅ Production-Grade Printer Preloaded & Ready to Print

Think of it as a part vending machine—your files, your material, your settings, all dialed in. Low-skill operators can run it confidently, with zero guesswork.

You’re not just getting a printer. You’re getting a proven manufacturing system in a box.

What You Get

A Complete, Field-Ready Solution.

We design and validate the perfect part, then deliver the entire production system—pre-loaded with the part file, the machine, and the right material.

WHY CHOOSE 3DCHIMERA?

With decades of engineering experience and deep additive expertise, we solve problems others can't. Whether it's reverse engineering a broken part or keeping a production line alive, we've done it.

Get Started