STARTER PATH

StarterIn-house inspection for teams getting started with quality control.

Starting at $10k+

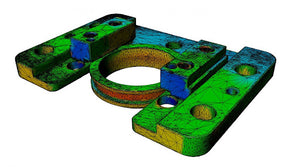

- CAD comparison and basic inspection

- Fast, portable part verification

- Ideal for engineering and small QA teams

System includes

- Shining3D Combo+

- Shining3D Inspect software

- Setup guidance and first-use support