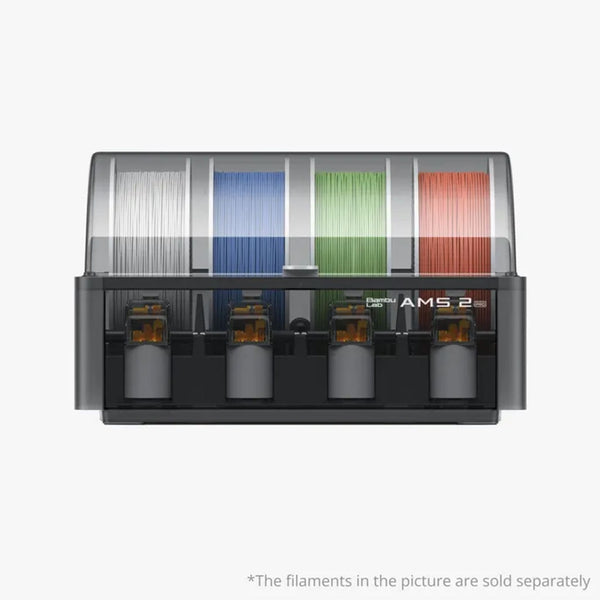

Bambu Lab AMS 2 Pro — Automatic Material & Filament Drying System

Ausverkauft

The AMS 2 Pro is the advanced material-management upgrade for serious 3D printing workflows — ideal for hobbyists, prosumers, and production shops alike.

With automatic spool switching, integrated drying, and seamless multi-material support, AMS 2 Pro automates filament handling so you can focus on designing and printing — not constantly swapping spools or managing moisture-sensitive materials.

Compatible with a wide range of Bambu Lab 3D printers, it brings enterprise-grade convenience to desktop and workshop printing.

- Multi-slot (4) automatic spool switching

- Integrated filament dryer — up to 65 °C

- Compatible with PLA, PETG, PA, PC, ABS, ASA, and more

- Compact footprint: 372×280×226 mm, 2.5 kg

- Expandable — chain multiple AMS units for up to 24 spools total

- Airtight housing + active moisture control

What’s in the Box: AMS unit, PTFE tubing, desiccant packs, bus cable / connection harness. Filament spools sold separately.

Key Features & Benefits of AMS 2 Pro

- Multi-spool, multi-material support — holds up to 4 spools simultaneously, enabling seamless multi-color or multi-material printing within a single job

- Automated spool switching and feeding — each slot has its own feed motor and gearing, allowing for hands-free filament changes without interrupting the print.

- Integrated filament drying & active humidity control — dries filament up to ~65 °C to keep moisture-sensitive materials (like nylon, PC, composites, etc.) print-ready and stable.

- Compact, robust build — rugged enclosure with a small footprint, ideal for desktop or workshop environments while still delivering industrial-grade reliability.

- Expandable & scalable configuration — multiple AMS units can be combined to increase spool capacity and support complex or large-scale printing workflows.

- Simplifies workflow & reduces downtime — eliminates manual spool swaps, material drying setups, and frequent pauses, making printing more efficient and predictable.

- Material flexibility — compatible with a broad range of filament types (standard and engineering filaments), giving you freedom to work with PLA, PETG, PC, ABS, composites, and more.

- Improved print stability & quality — by ensuring consistent, dry filament feed and automated switching, AMS 2 Pro helps reduce print failures, stringing, and moisture-related defects.

Use Cases & Ideal Users

- Multi-color or multi-material printing — perfect for designers, product modelers, or artists working with color transitions or dual-material builds.

- Engineering, industrial, or functional parts — especially when using moisture-sensitive filaments like PA, PC, Nylon, or composites; drying ensures consistent performance.

- Small-batch production / print farms — automates spool handling, reduces downtime, and increases throughput when running many prints with different materials.

- Development labs, prototyping houses, and OEMs — simplifies logistics for prototypes requiring different materials or colors.

Why 3DChimera?

At 3DChimera, we specialize in bridging professional 3D printing hardware and industrial-grade materials. When you buy AMS 2 Pro through us, you get:

- U.S.-based stock and fast shipping (Miami, FL)

- Expert support for integrating AMS with engineering-grade materials (e.g. PA, PC, composites)

- Guidance on optimal drying settings, spool handling, and multi-material workflows

- Access to material sourcing — from consumer filaments to high-temp and performance polymers