3DC Dyeformer - Dye System for 3D Printed Parts

In stock

**SPECIAL OFFER: FREE SHIPPING (No coupon code needed)**

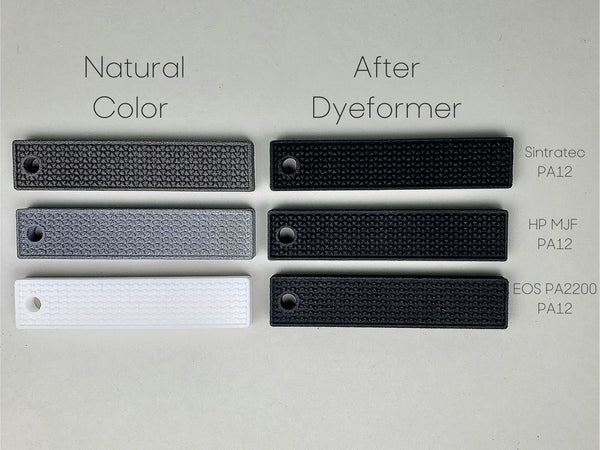

The Simple and Affordable Way To Dye SLS, MJF, SAF and Resin Parts

The Dyeformer was designed to take the complexity out of dyeing 3D printed parts. Gone are the days of guessing the perfect temperature, time, and dye formulation. With the perfectly portioned 3DC Dye Mix, the Dyeformer is able to dye your SLS and MJF parts repeatedly for 30 days with a single button press.

Features

One Button Operation

The 3DC Dyeformer comes pre-programmed with the ideal temperature, flow rate and time to dye PA12 parts. After the initial setup, you simply drop in your parts, hit start and walk away...the system does the rest! After an hour, the cycle is complete and the system chimes, letting you know it is time to remove your parts and place on the drying rack.

Now In Color

Now unlock the rainbow and dye any SLS, MJF, SAF or resin parts in one of our 8 new dye colors (Red, Orange, Yellow, Green, Blue, Purple, Teal & Magenta). Our color dyes are non-toxic and reusable for up to 24 hours.

For parts large and small!

The internal tank dimensions are 11.5 x 19.5 x 6 in for some huge SLS parts! For smaller parts, the standard stainless steel basket fits inside the tank perfectly with dimensions of 16 x 8 x 4 in, for a volume of over 500 in3! And the XL stainless steel basket is twice the volume for maximum throughput, with a size of 17 x 9.5 x 6in!!

How does it work?

The proprietary 3DC Dyeformer Dye Mix is combined with water and heated to a precise temperature, which helps to relax the polymer strands of nylon to permanently absorb the dye. After the process is complete, parts are left to dry and the dye remains in polymer.

What's Included

- Stainless steel dye tank

- Stainless steel small parts basket

- 1 bottle dye mix (black)

- Drying mat

- Power cord

- Product manual

- 1yr Warranty

- 24/7 Technical support

Specs

| Max Part Size | 19.5 x 11.5 x 6 in 495 x 292 x 152 mm |

| Max Part Volume | 1,345 in3 22,040 cc |

| Basket Size |

Standard - 16 x 8 x 4 in XL - 17 x 9.5 x 6 in |

| Max Tank Water Volume | 5.3 gal 20.1 L |

| Dye Cycle Time | 1hr |

| Black Dye : Water Ratio Grey Parts |

1 Bottle : 1 Tank |

| Black Dye : Water Ratio White Parts |

2 Bottles : 1Tank |

| Color Dye : Water Ratio All Parts |

1 Bottle : 1 Tank |

| Dye Reuse |

Black - Up to 30 days or 10-20kg of parts* *Dependent on surface area of parts |

| Overall Dimensions | 22.4 x 16.9 x 10.9 in 569 x 429 x 276 mm |

| Weight | 16.5 lbs 7.5 kg |

| Power |

120 V, 60 Hz, 15A, 1800 W max |

| HS Code (Dyeformer) | 8419.89.9580 |

| HS Code (Dye Mix) | 3204.13.10 |

Compatibility

This system was originally developed to complement the PA12 parts printed off of the Sintratec Kit and Sintratec S2.

The chemistry of this dye is compatible with all PA12 materials from any powder bed fusion 3D printing vendor (i.e. SLS, MJF, etc), including:

- Formlabs Fuse1 & Fuse1+

- Sintratec

- EOS

- 3D Systems

- Prodways

- HP MJF

- Sinterit

- XYZ

- Farsooon

- ALM

- AM Polymers

- And many more...